|

|

|

Dear

Subscriber,

We

at IRI have been wondering if the US is on the

verge of an energy revolution. Once again, we have

a blockbuster #1 article.What could be better for

the world than a clean replacement fuel which

allows us to say, "We have the

potential touse electricity as transportation fuel

without needing to change current

infrastructure." That is the best

summary of the breakthrough discovery from UCLA

just last month to store electricity very

compactly as alcohol. Hopefully the DOE is

listening and will offer billions to them instead

of to a solar company that goes

bankrupt.

Our

story #2 gives us the hope that solar cells will

organically integrate into all of the everyday

products, including clothing. It looks a lot more

hopeful than ever before with work done at the

University of Tokyo.

Fusion

just received a new shot in the arm with story #3

and Sandia Labs' simulation of a new magnetized

inertial fusion (MIF) method that predicts a 50

times more efficient than using X-rays. It's like

combining magnetic confinement (e.g., Tokamak)

with inertial confinement (laser bombardment) to

get the best of both worlds. Edging toward the

successful cavitation sonofusion known to work on

a microscopic scale, the MIF process maybe a

commercial zinger sooner than we

expected.

Story

#4 shows that new, unheard of materials are still

emerging, like porous metal films that are

transparent. With applications aimedat fuel cells,

batteries and solar energy, Cornell labs can make

such films from a variety of

metals.

Will

algae farms ever compete with imported or domestic

oil?Story #5 gives the bet to Sapphire energy with

the support of the National Renewable Energy Lab

and a loan guarantee from the US Agriculture Dept.

Though100 barrels of crude per day sounds like a

lot, the operation will have to at least triple in

order to become commercially competitive, which is

within reach. Only time will tell!

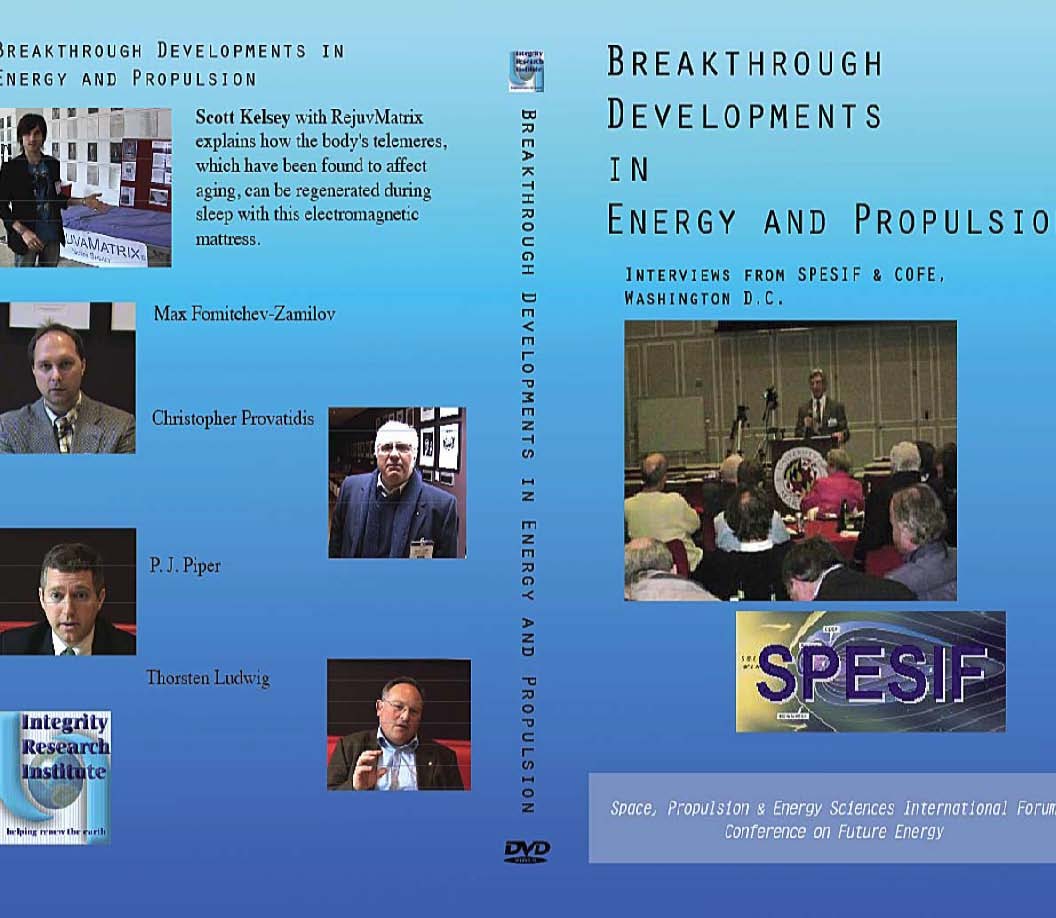

Note

that our wonderfully watchable and less than one

hour DVD from SPESIF 2011 is now available with a

discount (see below).

Thomas

Valone

Editor

www.IntegrityResearchInstitute.org | |

| |

|

1)

Producing Fuel with C02 and Sunlight at UCLA

Engineering |

By Wileen Wong

Kromhout March 29,

2012

http://newsroom.ucla.edu/portal/ucla/ucla-engineering-researchers-use-231103.aspx

|

|

Producing fuel with C02 and

sunlight | Today,

electrical energy generated by various methods is

still difficult to store efficiently. Chemical

batteries, hydraulic pumping and water splitting

suffer from low energy-density storage or

incompatibility with current transportation

infrastructure.

In a study published March 30 in the

journal Science, James Liao, UCLA's Ralph M.

Parsons Foundation Chair in Chemical Engineering,

and his team report a method for storing

electrical energy as chemical energy in higher

alcohols, which can be used as liquid

transportation fuels.

"The current way to store electricity is

with lithium ion batteries, in which the density

is low, but when you store it in liquid fuel, the

density could actually be very high," Liao said.

"In addition, we have the potential to use

electricity as transportation fuel without needing

to change current infrastructure."

Liao and his team genetically engineered

a lithoautotrophic microorganism known as

Ralstonia eutropha H16 to produce isobutanol and

3-methyl-1-butanol in an electro-bioreactor using

carbon dioxide as the sole carbon source and

electricity as the sole energy input.

Photosynthesis is the process of

converting light energy to chemical energy and

storing it in the bonds of sugar. There are two

parts to photosynthesis - a light reaction and a

dark reaction. The light reaction converts light

energy to chemical energy and must take place in

the light. The dark reaction, which converts CO2

to sugar, doesn't directly need light to

occur.

"We've been able to separate the light

reaction from the dark reaction and instead of

using biological photosynthesis, we are using

solar panels to convert the sunlight to electrical

energy, then to a chemical intermediate, and using

that to power carbon dioxide fixation to produce

the fuel," Liao said. "This method could be more

efficient than the biological system."

Liao explained that with biological

systems, the plants used require large areas of

agricultural land. However, because Liao's method

does not require the light and dark reactions to

take place together, solar panels, for example,

can be built in the desert or on rooftops.

Theoretically, the hydrogen generated by

solar electricity can drive CO2 conversion in

lithoautotrophic microorganisms engineered to

synthesize high-energy density liquid fuels. But

the low solubility, low mass-transfer rate and the

safety issues surrounding hydrogen limit the

efficiency and scalability of such processes.

Instead Liao's team found formic acid to be a

favorable substitute and efficient energy

carrier.

"Instead of using hydrogen, we use formic

acid as the intermediary," Liao said. "We use

electricity to generate formic acid and then use

the formic acid to power the CO2 fixation in

bacteria in the dark to produce isobutanol and

higher alcohols."

The electrochemical formate production

and the biological CO2 fixation and higher alcohol

synthesis now open up the possibility of

electricity-driven bioconversion of CO2 to a

variety of chemicals. In addition, the

transformation of formate into liquid fuel will

also play an important role in the biomass

refinery process, according to Liao.

"We've demonstrated the principle, and

now we think we can scale up," he said. "That's

our next step."

The study was funded by a grant from the

U.S. Department of Energy's Advanced Research

Projects Agency-Energy (ARPA-E).

The UCLA Henry Samueli

School of Engineering and Applied Science,

established in 1945, offers 28 academic and

professional degree programs and has an enrollment

of more than 5,000 students. The school's

distinguished faculty are leading research to

address many of the critical challenges of the

21st century, including renewable energy, clean

water, health care, wireless sensing and

networking, and cybersecurity. Ranked among the

top 10 engineering schools at public universities

nationwide, the school is home to nine

multimillion-dollar interdisciplinary research

centers in wireless sensor systems,

nanoelectronics, nanomedicine, renewable energy,

customized computing, and the smart grid, all

funded by federal and private agencies.

back

to table of contents

|

|

2) Solar Cell Thinner Than

Spider Silk Could Power Internet

of

Things |

|

Christopher Mims

04/04/2012 Technology

Review

http://www.technologyreview.com/blog/mimssbits/27700/?nlid=nlenrg&nld=2012-04-09

Will

ephemeral plastic solar cells make ubiquitous

sensor networks a reality?

When you think about how

to power a distributed network of environmental

sensors--the kind we'll want to have in order to

connect the entirety of

our physical world to the Internet of

Things--the

answer is obvious: solar power. Most of these

sensors are by nature too tiny to have access to

much of a temperature gradient, and a steady

supply of vibrations isn't always available.

Batteries have limited lifespans and add bulk and

expense.

That's one of the reasons

that organic and polymer-based solar cells are so

interesting, particularly the latest development:

A polymer-based (i.e. plastic) solar cell thinner

than spider silk that can be bent and crumpled and

still produces power

From the abstract of the

paper announcing

their development:

These ultrathin organic

solar cells are over ten times thinner, lighter

and more flexible than any other solar cell of

any technology to date.

This solar plastic only

converts 4.2 percent of

the sun's energy into electricity, which is awful by the

standards of conventional polycrystalline solar

cells, but absolutely miraculous when you consider

how thin and versatile this material could

be.

For example, Tsuyoshi

Sekitani from the University of Tokyo, one of the

researchers on this project, told the AFP that this material could

be worn on clothing like a badge, to power a

personal health monitor. So why not a thin film

under a protective shield, on the back of gadgets,

so that prolonging their battery life is as simple

as leaving them in a sunny spot?

When it comes to the

Internet of Things, tiny sensors require tiny

amounts of energy, and that's exactly what

organic solar cells can provide. Price and size

are the factors that will determine whether or not

they become ubiquitous, and this announcement

suggests that it's only a matter of time before

both requirements are met by organic solar

cells.

or get in touch

back to

table of contents

|

|

3)

Nuclear

Fusion Simulation Shows High-Gain Energy

Output |

Sandia

Lab Press Release March

20, 2012

https://share.sandia.gov/news/resources/news_releases/z-fusion-energy-output/

Component

testing under way at Sandia's Z accelerator for

fast-firing magnetic method

ALBUQUERQUE,

N.M. - High-gain nuclear fusion could be achieved

in a preheated cylindrical container immersed in

strong magnetic fields, according to a series of

computer simulations performed at Sandia National

Laboratories.

The

simulations show the release of output energy that

was, remarkably, many times greater than the

energy fed into the container's liner. The method

appears to be 50 times more efficient than using

X-rays - a previous favorite at Sandia - to drive

implosions of targeted materials to create fusion

conditions.

"People

didn't think there was a high-gain option for

magnetized inertial fusion (MIF) but these

numerical simulations show there is," said Sandia

researcher Steve Slutz, the paper's lead author.

"Now we have to see if nature will let us do it.

In principle, we don't know why we can't."

High-gain

fusion means getting substantially more energy out

of a material than is put into it. Inertial refers

to the compression in situ over nanoseconds of a

small amount of targeted fuel.

Such

fusion eventually could produce reliable

electricity from seawater, the most plentiful

material on earth, rather than from the raw

materials used by other methods: uranium, coal,

oil, gas, sun or wind. In the simulations, the

output demonstrated was 100 times that of a 60

million amperes (MA) input current. The output

rose steeply as the current increased: 1,000 times

input was achieved from an incoming pulse of 70

MA.

Since

Sandia's Z machine can bring a maximum of only 26

MA to bear upon a target, the researchers would be

happy with a proof-of-principle result called

scientific break-even, in which the amount of

energy leaving the target equals the amount of

energy put into the deuterium-tritium fuel.

This

has never been achieved in the laboratory and

would be a valuable addition to fusion science,

said Slutz.

Inertial

fusion would provide better data for increasingly

accurate simulations of nuclear explosions, which

is valuable because the U.S. last tested a weapon

in its aging nuclear stockpile in 1992.

The

MIF technique heats the fusion fuel

(deuterium-tritium) by compression as in normal

inertial fusion, but uses a magnetic field to

suppress heat loss during implosion. The magnetic

field acts like a kind of shower curtain to

prevent charged particles like electrons and alpha

particles from leaving the party early and

draining energy from the reaction.

The

simulated process relies upon a single, relatively

low-powered laser to preheat a deuterium-tritium

gas mixture that sits within a small liner.

At

the top and bottom of the liner are two slightly

larger coils that, when electrically powered,

create a joined vertical magnetic field that

penetrates into the liner, reducing energy loss

from charged particles attempting to escape

through the liner's walls.

An

extremely strong magnetic field is created on the

surface of the liner by a separate, very powerful

electrical current, generated by a pulsed power

accelerator such as Z. The force of this huge

magnetic field pushes the liner inward to a

fraction of its original diameter. It also

compresses the magnetic field emanating from the

coils. The combination is powerful enough to force

atoms of gaseous fuel into intimate contact with

each other, fusing them.

Heat

released from that reaction raised the gaseous

fuel's temperature high enough to ignite a layer

of frozen and therefore denser deuterium-tritium

fuel coating the inside of the liner. The heat

transfer is similar to the way kindling heats a

log: when the log ignites, the real heat - here

high-yield fusion from ignited frozen fuel -

commences.

Tests

of physical equipment necessary to validate the

computer simulations are already under way at Z,

and a laboratory result is expected by late 2013,

said Sandia engineer Dean Rovang.

Portions

of the design are slated to receive their first

tests in March and continue into early winter.

Sandia has performed preliminary tests of the

coils.

Potential

problems involve controlling instabilities in the

liner and in the magnetic field that might prevent

the fuel from constricting evenly, an essential

condition for a useful implosion. Even isolating

the factors contributing to this

hundred-nanosecond-long compression event, in

order to adjust them, will be challenging.

"Whatever

the difficulties," said Sandia manager Daniel

Sinars, "we still want to find the answer to what

Slutz (and co-author Roger Vesey) propose: Can

magnetically driven inertial fusion work? We owe

it to the country to understand how realistic this

possibility is."

The

work, reported in the Jan. 13 issue of

Physical Review Letters, was supported by

Sandia's Laboratory Directed Research and

Development office and by the National Nuclear

Security Administration.

Sandia

National Laboratories is a multi-program

laboratory operated by Sandia Corporation, a

wholly owned subsidiary of Lockheed Martin

company, for the U.S. Department of Energy's

National Nuclear Security Administration. With

main facilities in Albuquerque, N.M., and

Livermore, Calif., Sandia has major R&D

responsibilities in national security, energy and

environmental technologies and economic

competitiveness.

Sandia

news media contact: Neal Singer, nsinger@sandia.gov (505)

845-7078

|

|

4)

Tunable'

Metal Nanostructures for Fuel Cells,

Batteries

and Solar

Energy |

Bill Steele, CHRONICLE,

April 2012

http://www.solarfeeds.com/tunable-metal-nanostructures-for-fuel-cells-batteries-and-solar/

For

catalysts in fuel cells and electrodes in

batteries, engineers would like to manufacture

metal films that are porous, to make more surface

area available for chemical reactions, and highly

conductive, to carry off the electricity. The

latter has been a frustrating

challenge.

But Cornell chemists have now

developed a way to make porous metal films with up

to 1,000 times the electrical conductivity offered

by previous methods. Their technique also opens

the door to creating a wide variety of metal

nanostructures for engineering and biomedical

applications, the researchers said.

The

results of several years of experimentation are

described March 18 online edition of the journal

Nature Materials.

"We have reached

unprecedented levels of control on composition,

nanostructure and functionality -- for example,

conductivity -- of the resulting materials, all

with a simple 'one-pot' mix-and-heat approach,"

said senior author Ulrich Wiesner, the Spencer T.

Olin Professor of Engineering.

The

new method builds on the "sol-gel process,"

already familiar to chemists. Certain compounds of

silicon mixed with solvents will self-assemble

into a structure of silicon dioxide (i.e., glass)

honeycombed with nanometer-scaled pores. The

challenge facing the researchers was to add metal

to create a porous structure that conducts

electricity.

About 10 years ago,

Wiesner's research group, collaborating with the

Cornell Fuel Cell Institute, tried using the

sol-gel process with the catalysts that pull

protons off of fuel molecules to generate

electricity. They needed materials that would pass

high current, but adding more than a small amount

of metal disrupted the sol-gel process, explained

Scott Warren, first author of the Nature Materials

paper.

Warren, who was then a Ph.D. student

in Wiesner's group and is now a researcher at

Northwestern University, hit on the idea of using

an amino acid to link metal atoms to silica

molecules, because he had realized that one end of

the amino acid molecule has an affinity for silica

and the other end for metals.

"If there was

a way to directly attach the metal to the silica

sol-gel precursor then we would prevent this phase

separation that was disrupting the self-assembly

process," he explained.

|

| Just about any element in

the periodic table can be used (shown in blue

and pink). Those in blue can be bought off the

shelf. |

The

immediate result is a nanostructure of metal,

silica and carbon, with much more metal than had

been possible before, greatly increasing

conductivity. The silica and carbon can be

removed, leaving porous metal. But a silica-metal

structure would hold its shape at the high

temperatures found in some fuel cells, Warren

noted, and removing just the silica to leave a

carbon-metal complex offers other possibilities,

including larger pores.

The researchers

report a wide range of experiments showing that

their process can be used to make "a library of

materials with a high degree of control over

composition and structure." They have built

structures of almost every metal in the periodic

table, and with additional chemistry can "tune"

the dimensions of the pores in a range from 10 to

500 nanometers. They have also made metal-filled

silica nanoparticles small enough to be ingested

and secreted by humans, with possible biomedical

applications. Wiesner's group is also known for

creating "Cornell dots," which encapsulate dyes in

silica nanoparticles, so a possible future

application of the sol-gel process might be to

build Graetzel solar cells, which contain

light-sensitive dyes. Michael Graetzel of the

École Polytechnique Fédérale de Lausanne and

innovator of the Graetzel cell is a co-author of

the new paper. The measurement of the

record-setting electrical conductivity was

performed in his laboratory.

The research

has been supported by the Department of Energy

and, through several channels, the National

Science Foundation.

|

|

5) Sapphire Energy

Raises $144 Million for an Algae

Farm |

Kevin

Bulls, MIT Technology Review, April 6,

2012

This

week, algae-biofuel startup Sapphire Energy

announced it has received $144 million in new

funding, which brings its total to over $300

million.

The

company, which is less than five years old, has

been moving quickly to build a 300-acre algae farm

as a large-scale demonstration of its process for

making algae oils. The U.S. government has

supplied over $100 million of the investments,

including a $50 million Recovery Act grant

designed in part to spur job creation.

But

Sapphire's rapid expansion raises the question of

whether it is scaling up its technology too soon.

Some of its ideas for reducing the cost of algae

fuels are at too early a stage to be implemented

at the new farm. Yet these technologies might

prove vital to making its fuels competitive.

Knowing

when to move technologies out of the lab and into

large-scale demonstrations is a perennial

challenge for energy startups. According to some

experts, Range Fuels, a startup founded to produce

ethanol from wood chips, foundered because it

built a large-scale plant too soon, before the

bugs had been worked out of its technology at a

smaller scale. As a result, the plant didn't work

well enough to be economical.

The

new funding will allow Sapphire to finish building

its algae farm, near the small town of Columbus,

New Mexico, just north of the U.S.-Mexico border.

A 100-acre segment of the farm has already been

finished, and when the whole project is complete,

by 2014, Sapphire will have the capacity to

produce about 1.5 million gallons of algae crude

oil, which can be shipped to refineries to make

chemicals and fuels such as diesel and

gasoline.

Algae

is attractive as a source of fuel because the

microörganisms naturally make large amounts of oil

and can be grown in ponds filled with brackish or

salt water, so they don't use up fresh water

supplies or quality farmland. But algae are

expensive to grow and harvest, so previously

they've only been used commercially to produce

relatively high-value products such as cosmetics

and nutritional supplements.

Sapphire

hopes to lower the cost of producing algae fuels

by changing every part of the production process.

That includes increasing the quality and the

amount of oil produced, reducing the cost of

building ponds, and developing low-cost ways to

harvest the oil. The company aims to have a

product that's competitive with oil priced at $85

per barrel, and it expects to meet this goal once

it reaches full-scale production in about six

years. Oil costs over $100 a barrel now.

Achieving

these cost targets will require significant

innovation. Last year, a pair of studies from the

National Renewable Energy Laboratory in Golden,

Colorado, concluded that algae-based diesel made

by scaling up existing algae technologies would

cost several times as much as conventional diesel.

According to one of the studies, it would cost

about $9.84 per gallon to make algae diesel, as

opposed to $2.60 per gallon for petro-diesel, at

January 2011 costs. Other studies have estimated

even higher costs.

Increasing

the amount of oil that algae makes is one of the

most promising ways to reduce costs. A number of

other algae-biofuels companies are genetically

engineering their algae to increase production,

but Sapphire, instead, has developed a fast way to

breed algae, select those with traits that can

improve oil production, and make oil that

resembles crude oil closely enough that it can be

processed in ordinary refineries.

Sapphire

has also bred algae that can flourish in open

ponds. Other algae-biofuels companies use closed

containers, which are more expensive but can help

protect the algae from predators, fungal diseases,

and other strains of algae that might take over a

pond. Sapphire has bred disease-resistant algae

that can grow under harsh conditions, such as high

pH or salinity, that most other organisms can't

tolerate, reducing competition. It has also made

them resistant to certain chemicals that inhibit

the growth of other organisms.

Another

major challenge is harvesting the algae. It takes

about 1,000 grams of water to grow 1 gram of

algae, and separating the two efficiently and

extracting the oil can require a lot of energy.

Borrowing techniques from water-treatment plants,

Sapphire treats the algae with chemicals that

cause them to clump together. The algae can be

"squeegeed off the surface" says Tim Zenk,

Sapphire Energy's vice president of corporate

affairs. The result is wet slurry that still

contains a lot of water. Sapphire treats that with

solvents at high pressures and temperatures to

make three streams of products: algae oil,

nutrients such as phosphates, and the leftover

biomass. The oil goes to a refinery, and the

nutrients and biomass are used to feed more

algae.

The

company is finding ways to reduce other costs.

Rather than building concrete ponds, it is

building cheaper ponds out of dirt and waterproof

liners. It plans eventually to do away with the

liners and make ponds that resemble rice paddies.

Sapphire is also replacing energy-intensive paddle

wheels used to circulate the algae with more

efficient pumps, and is planning to design systems

that use only the wind that sweeps across the New

Mexico deserts for circulation.

The

company is working with Munich-based Linde Group

to develop a low-cost way to supply the algae with

carbon dioxide, which is key to high productivity.

Linde has developed systems for supplying

greenhouses with carbon dioxide from a

refinery.

Finally,

Zenk says, the company may eventually turn to

genetic engineering to further improve the

performance of its algae.

When

complete, the new 300-acre algae farm project is

expected to produce about 100 barrels of algae

crude per day, or 35,000 a year. Zenk says the

process won't be commercially viable without the

economies of scale that will come with much, much

bigger farms-1,000 to 5,000 acres.

Sapphire

is a major beneficiary of the U.S. government. It

received a $50 million grant connected to the 2009

Recovery Act and a $54 million loan guarantee from

the U.S. Department of Agriculture. Its first

customers may be the U.S. military, which is

evaluating its fuels. Sapphire's early funders

included Bill Gates and a Rockefeller family fund.

Monsanto is another major funder. It has an

R&D agreement with Sapphire to identify genes

in algae that might make corn, cotton, and

soybeans more resistant to drought and other

stress, and increase their yield.

Phil

Pienkos, a research scientist at the National

Renewable Energy Lab, says that Sapphire is doing

a number of good things to reduce costs. Yet he

says making algae fuels competitive will be a

challenge. "It takes a certain amount of faith

that there is going to be a business there," he

says.

|

About Integrity

Research Institute

Future

Energy eNews is

provided as a public service from Integrity Research

Institute, a

Non-Profit dedicated to educating the public

on eco-friendly emerging energy technologies.

FREE copy

of the 30 minute DVD "Progress in Future Energy"

is available by sending an email with "Free DVD" in subject

and mailing address in

body.

Your

generous support is welcome by making a tax

deductible donation on our

secure website | | | |

- Scott Kelsey,

Missouri State, explaining Rejuvamatrix,

Pulsed EMF therapy to increase the length of DNA

telomeres, which directly affect our lifespan.

- Max

Formitchev-Zamilov, Penn State,

discussing Cavitation Induced Fusion, that will

soon provide power generation and heat production.

- Christopher

Provaditis, from Greece, explaining

Inertial Propulsion and who teamed up recently with

Boeing for their space satellites.

- PJ Piper

of QM Power, discussing the

motor invented by Charles Flynn, with a revolutionary

parallel path that gives double and triple

efficiency.

- Dr Thorsten

Ludwig from Germany (GASE)

discussing the mysterious Hans Coler motor that WWII

British Intelligence researched.

|

|

| | | |