|

|

|

Dear

Subscriber,

Please

support our next Conference on Future

Energy (SPESIF-COFE5) by sending in

your abstract for a paper. The deadline has been

extended to October 15, 2011 if you can also

add a draft of your paper too. We also look

forward to having one or more demonstrations at

the conference as well, so those proposed papers

or proposed presentations will be given special

attention. Exhibit tables are available FREE to

presenters upon request.

We are

excited to see any unconventional energy generator

get to the level of a one megawatt demonstration

plant. That is what is expected of Rossi's E-cats

in the #1 article in October. The video online

gives a walk-through tour of the plant. Of course,

thermal energy still needs to be converted to

electrical, with the usual energy losses, but most

of the conventional utility generation in the

country has that problem. In related news, the low

energy nuclear reaction (LENR) field is heating up

and so a two-day course is being offered on the

developments in LENR on October 3-4, 2011 at the

Hyatt Regency in Crystal City VA by a start-up company called

NUCAT.

Talking

about heat, our #2 story has another approach for

dealing with the wanton wastefulness of industrial

processes by converting it with polymer

pyroelectric materials into electricity.

Two

years after Dr. Glen Gordon's last contribution to

the field of bioelectromagnetics, his EM-Pulse still makes

news with the #3 story that revisits the

importance of a NASA study which he relied upon.

Glen used to emphasize the value of a fast rise

time for any pulsed electromagnetic (PEMF) device

in order to stimulate the HSP70 protein which is a

restorative and regenerative protein that repairs

any number of injuries before inflammation occurs,

so the sooner such a device is used, the better.

Now the NASA study is online for a free download

and IRI still has a few of his EM-Pulse devices

available.

It's

great to see new applications of battery

technology where no man has gone before, like on a

ship (Story #4) and for lightweight applications

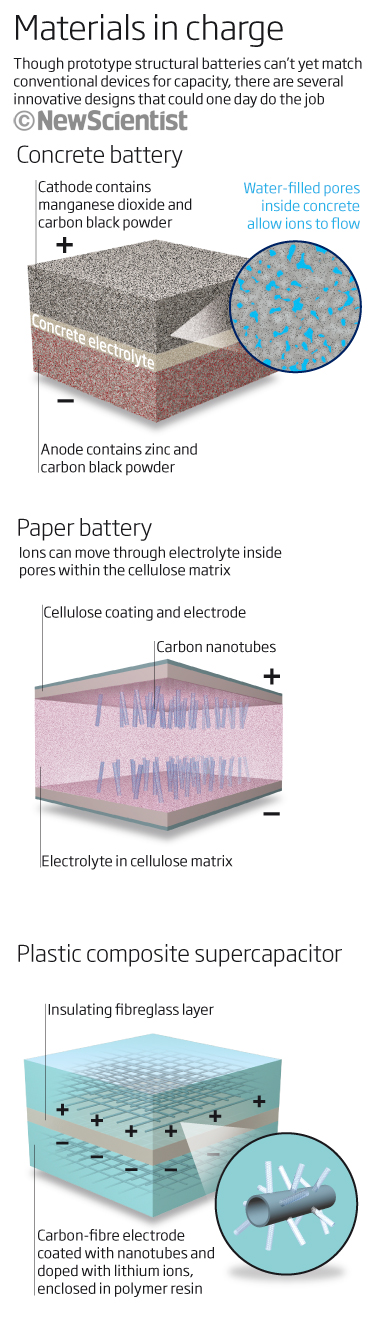

with carbon fiber, concrete or plastic. (Story

#5).

Thomas Valone,

PhD, PE Editor

www.IntegrityResearchInstitute.org | |

| |

|

1)

Rossi's One Megawatt

Plant |

By: Mats Lewan

Publicerad igår, 07:00 Sept. 15, 2011

http://www.nyteknik.se/nyheter/energi_miljo/energi/article3264361.ece

Ny Teknik got a look at the plant

last week in Bologna, where it had been assembled

from parts supposedly manufactured in Rossi's

factory in Miami, Florida.

The plant consists of 52 'E-cats' of a new

model that Rossi says he developed this spring,

partly through discussions with the Swedish

physicists Sven Kullander and Hanno Essen, mainly

regarding research done by Hidetsugu Ikegami, a

professor emeritus at Osaka University in

Japan.

The plant was supposed originally to consist of 100 units of an

early model, rated at a power output of ten

kilowatts. When manufacturing started Rossi stated

that he instead chose a smaller, more stable model

with a power of about three kilowatts, and that

300 such units would then be used.

In July, Rossi changed his mind after

claiming to have reached 27 kilowatts of power

output with the latest model, then discarded the

previously manufactured units.

The 52 units were mounted in four rows along both

sides of a 20-foot container. On the front of each

unit is a valve for filling hydrogen, as well as

electrical connections to the electric resistance

used to 'ignite' the reaction.

Steam outlet hoses are connected to a

single isolated thick tube that runs along both

sides and ends on the outside of the container's

short side. On the outside is a water pump for

water intake.

The plant was initially scheduled to be transported to Greece for

the opening in October, in co-operation with the

Greek company Defkalion Green Technologies.

After Rossi's breach of

contract with Defkalion in August and after

Rossi had established contacts with an American

customer, the container is now instead being

shipped to the United States.

According to Rossi, the launch is

scheduled as planned in October, and will be controlled by a "very

important entity" in the U.S. At the  launch a complementary part will be

included to attain a power-output rating of one

megawatt, as the 52 units will be operated at

reduced power levels to ensure stability even at

intervals with self-sustained

operation. launch a complementary part will be

included to attain a power-output rating of one

megawatt, as the 52 units will be operated at

reduced power levels to ensure stability even at

intervals with self-sustained

operation.

Here it is: the plant that according to inventor

Andrea Rossi will produce one megawatt of thermal

energy via an unknown reaction in his 'energy

catalyzer'. The plant is now being shipped to the

United States.

Ny Teknik assisted at a recent test of the

new model running in self-sustained mode - read our report

here.

Video Demo online: http://www.nyteknik.se/nyheter/energi_miljo/energi/article3264361.ece

READ MORE: Our complete coverage on Rossi's E-cat can be found

here.

RELATED

NEWS

A SHORT COURSE IN

LENR

"Perspectives

on Low Energy Nuclear Reactions" is scheduled for

3 and 4 October of this year at the Hyatt Regency

Hotel in Crystal City very near Washington DC. The

motivation for the course is the significantly

increasing interest in our field. It will

provide an effective way to learn the background,

status and prospects for LENR. Instructors

for the course are Grabowski, Hagelstein, Imam,

Kidwell, McKubre, Melich and Nagel.

The

web site for the course is: http://nucat-energy.com/short-course/.

The

course is sponsored by a new company NUCAT Energy

LLC. The name NUCATderives from the two

physical levels critical to LENR, namely NUClear

and ATomic.

|

|

2) Polymer

Sandwich for Heat Conversion from

Waste |

21 July 2011 by Ferris

Jabr

http://www.newscientist.com/article/mg21128215.900-polymer-sandwich-harvests-electricity-from-waste-heat.html

IN 314 BC the Greek philosopher

Theophrastus noticed something unusual: when he

heated a black crystalline rock called tourmaline,

it would suddenly attract ash and bits of straw.

He had observed what we now call pyroelectricity -

the ability of certain crystals to produce a

voltage briefly when heated or cooled. Now the

same phenomenon is being used to convert waste

heat into electricity.

Nearly 55 per cent of all the energy

generated in the US in 2009 was lost as waste

heat, according to research by the

Lawrence Livermore National Laboratory in

California. There have been many attempts at using

this waste heat to generate electricity, so far

with only limited success.

Pyroelectricity could be the key, say

Scott Hunter and

colleagues at Oak Ridge National Laboratory in

Tennessee. They have built an energy harvester

that sandwiches a layer of pyroelectric polymer

between two electrodes made from different metals.

Just a few millimetres long, the device is

deployed by wedging it between a hot surface and a

cold surface - between a computer chip and a fan

inside a laptop, for example. Crucially, the

device is anchored to the hot surface alone and so

acts as a cantilever - a beam supported at one

end.

As the device warms, the polymer

expands more than the electrode close to the cold

surface, and the whole device bends like the

bimetallic strip in a thermostat. It droops toward

the cold surface, where it cools and then springs

back toward the hot surface, warming up again.

Soon the cantilever is thrumming between the hot

and cold surfaces like the hammer of a wind-up

alarm clock. Each time it is heated, the polymer

generates a small amount of electricity which is

stored in a capacitor (Proceedings of SPIE,

DOI:

10.1117/12.882125).

Previous attempts at using

pyroelectric materials to recycle waste heat have

only managed to turn 2 per cent of the heat into

electricity. Hunter believes his device could

achieve an efficiency of between 10 and 30 per

cent.

Hunter says the device can also

convert heat in exhaust gases into electricity. It

might even be used to capture the energy that

solar cells lose as heat, he says. Energy

generation aside, he adds that the devices could

soak up enough heat to play a significant role in

cooling laptops and data centres.

Laurent Pilon of

the University of California, Los Angeles, who

also studies pyroelectric energy harvesting, says

he likes the compactness of the device and its

relative simplicity, but has some doubts about the

potential efficiency. "I think some of their

expectations are a little exaggerated," he says.

"They are relying on conduction to heat the

device, which is a slow process." He and other

groups have used fluids to heat or chill a

pyroelectric material. This is much quicker,

though the need to pump the fluid around does

consume some of the energy

generated.

|

3)

Pulsed Electro-Magnetic Fields (PEMF) Four

Year Study by NASA

|

May 22,

2011 // by

drashoksinghal100 // Blog

// 8Comments

Ed. Note: Dr. Glen

Gordon, a former COFE speaker, washighly

influenced to develop the EM-Pulse technology that

IRI still sells, based on the preliminary results

of this NASA study. -

TV

|

| Glen Gordon, MD, EM Pulse

PEMF

Device |

NASA 4-year

collaborative study on the efficacy of

electromagnetic fields to stimulate growth and

repair in mammalian tissues has definitive results

according to CHIEF INVESTIGATOR: Thomas J.

Goodwin, Ph.D.Lyndon B Johnson

SpaceCenter.

PURPOSE: This four year

study used human donors "to define the most

effectiveelectromagnetic fields for enhancing

growth and repair in mammalian tissues."

To utilize "nerve

tissue which has been refractory to efforts to

stimulategrowth or enhance its repair regardless

of the energy used." (all othertissues have

demonstrated growth and repair stimulation with

appropriate PEMF)

To define a PEMF

technology that would "duplicate mature, three

dimensionalmorphology between neuronal cells and

feeder (glial) cells, which has not beenpreviously

accomplished."

RESULTS: The PEMF used

in the study "caused accelerated growth rate and

betterorganized morphology over controls", and

resulted in "greater cellviability" (85% vs.

65%).

In the gene discovery

array (chip technology that surveyed 10,000 human

genes),the investigators found up-regulation of

150 genes associated with growth andcell

restoration.

T.Goodwin (personal

communication) " PEMF shut down each dysregulatory

gene we studied".

NASA's CONCLUSION:

"The up-regulation of

these genes is in no manner marginal (1.7-8.4

logs) with genesites for collagen production and

growth the most actively stimulated."

"We have clearly

demonstrated the bioelectric/biochemical

potentiation of nervestimulation and restoration

in humans as a documented reality".

"The most effective

electromagnetic field for repair of trauma was

square wave witha rapid rate of change (dB/dt)

which saw cell growth increased up to

4.0times."

They further noted that

"slowly varying (millisecond pulse, sine wave) or

nonvarying DC (CW lasers, magnets) had little to

no effect."

Final

Recommendation: "One may use square wave

EM fields with rapid rate ofchange for":

1) repairing

traumatized tissues

2) moderating some

neurodegenerative diseases

3) developing

tissues for transplantation

PEMF

PROVIDES:

·GREATER

CELL VIABILITY

·ACCELERATED CELL GROWTH·BETTER

ORGANIZED CELL MORPHOLOGY·UPREGULATION OF

GENESRELATED TO COLLAGEN PRODUCTION

·UP

REGULATION OF GENES RELATED TO CELL RESTORATION

AND GROWTH·BIOELECTRIC POTENTIATIONOF NERVE

STIMULATION AND RESTORATION·HIGH-SPEED SQUARE WAVE

INCREASEDCELL GROWTH FOUR-TIMES

FASTER.

For More

Information:

http://www.integrityresearchinstitute.org/catalog/bioelectric.html

*the first study

to clarify technologies and efficacy parameters

for tissue growthand restoration

|

| 4)

Zero-Emission Hydrogen Powered Prototype Vessel

|

ScienceDaily (Sep. 2,

2011) - Swiss Federal Laboratories for

Materials Science and Technology (EMPA)

Researchers have been operating a

canal boat with a fuel cell drive for three years

now. In the world of shipbuilding, however,

different rules apply than those in the automobile

manufacturing industries. Weight is of practically

no significance, but the propulsion plant must

have an operating lifetime as long as that of the

boat itself. The hydride storage system -- the

hydrogen tank -- must meet this challenging

requirement.

One

of the most efficient means of transporting

freight is by ship. However, many of the ships

sailing today are powered by aging diesel motors

fitted with neither exhaust cleaning equipment nor

or modern control systems. Three years ago the

University of Birmingham initiated an ambitious

trial, converting an old canal barge to use

hydrogen fuel.

|

| The Ross Barlow Zero

Emission Canal

Vessel |

The

old diesel motor, drive system and fuel tank were

removed and replaced with a high efficiency

electric motor, a battery pack for short-term

energy supply and a fuel cell with a hydrogen

storage system to charge the batteries. In

September 2007 the converted boat, the "Ross

Barlow," was launched on its maiden voyage on

Britain's 3500 km long canal system. Last year the

barge made its longest voyage to date, of four

days duration and 105 km length, negotiating no

less than 58 locks. A good opportunity to look

back and take stock.

Mass-produced

drive system meets tailor-made storage

technology

The

first task to be done in converting the 18 m long

steel-hulled barge was to calculate the power

requirements. Based on experience with other

battery driven canal boats it was decided to use a

10 kW permanent magnet motor. To provide energy

for longer trips a commercial fuel cell delivering

1 kW of power was chosen. This system was

originally designed as an uninterruptible power

supply (UPS) for use in the telephone industry.

The capacity of the fuel cell was, however

insufficient to power the boat directly, so the

"Ross Barlow" was also fitted with a 47 kWh buffer

battery. Lead acid batteries were used for this

purpose since they are low maintenance, low-priced

and easy to charge. The weight of the battery pack

is of no consequence when used in an inland

waterways vessel.

The

hydrogen supply for the fuel cell was provided by

hydride storage system developed by Empa and

partly financed by the Swiss Federal Office of

Energy (SFOE). This device can store hydrogen with

an energy content of 50 kWh, which is equivalent

to 20 pressurized gas cylinders each of 10 Liter

capacity. The storage material consists of an

alloy of titanium, zirconium, manganese, vanadium

and iron in powder form which is packed into

sealed steel tubes. The powder absorbs hydrogen,

thus acting as a storage medium, only releasing it

when heated. Since when "filling up" with hydrogen

the metal powder generates heat which must be

removed, each storage module is located in a water

tank which can be warmed or cooled as necessary,

In addition the ship is fitted with a solar panel

which can supply up to 320 W of electric

power.

|

| The hydride storage system

developed by Empa was partly financed by the

Swiss Federal Office of Energy

(SFOE). |

Charging

and discharging cycles -- for the next 100

years!

The

journey through canals and locks makes widely

varying demands on the barge's electrical supply.

To save wear and tear on the fuel cell, the motor

draws its current from the lead acid batteries

during routine sailing. A typical journey takes 4

to 6 hours during which time the canal boat uses

12 to 18 kWh of power. In continuous operation the

fuel cell delivers 24 kWh of energy per day. This

also powers the electronic monitoring system,

leaving about 19 kWh with which to charge the

buffer battery pack -- enough energy for a daily

journey lasting six hours.

The

reliability and operational lifetime of the metal

hydride storage system was tested in the

laboratory during its development. In practical

terms this means that when used to power the "Ross

Barlow," if the ship is assumed to travel 650 km

per year through the British canal system, it

would need refueling once a month with hydrogen.

In this case the hydrogen storage system would

have an operating lifetime in excess of 100 years,

and would therefore comfortably outlast the useful

lifetime of the barge itself.

The

results of the test voyage

During

the 105 km, four-day summer test journey a total

of 106 kWh of electric energy was consumed on the

"Ross Barlow," including lighting and recharging

the crew's mobile telephones and laptop

computers.

The

batteries supplied 71 per cent of this energy, the

hydrogen fuel cell 25 per cent and the solar panel

4 per cent. There was unanimous praise from the

crew for the practically silent way the boat

sailed. Also notable was that when waiting in a

lock the "Ross Barlow" was not engulfed by its own

diesel fumes. The boat which accompanied it (which

was about the same size) used some 50 L of diesel,

resulting in a CO2 emission of approximately 133

kg. The "Ross Barlow" on the other hand produced

no CO2 during its voyage, assuming that the

hydrogen it used was derived from renewable

sources and delivered free of emissions to the

refueling point on the bank of the canal.

back to table of

contents

|

| 5)

Recharging the Battery: Hidden

Power |

by James Mitchell Crow Aug.

25,2011, New Scientist issue 2827.

http://www.newscientist.com/article/mg21128272.300-recharging-the-battery.html?full=true

IF THERE is one thing that symbolises the

incredible success - and dismal failure - of

21st-century technology, it is the battery. Each

year we spend some $50 billion on the things,

mostly to go in our cameras, cellphones and

laptops. They give us abilities our parents could

only dream of. Yet batteries are also a titanic

headache, both for engineers who must squeeze

these objects into tight spaces, and for the

millions of us who curse them whenever our gadgets

run out of juice.

Help could finally be at hand, though, now

that researchers are starting to rethink

electrical storage from the bottom up. They

foresee a time when the very fabric of modern life

- ordinary materials such as plastics and concrete

- will hold much of the electricity we need.

Utilising familiar stuff in this way not only

promises to keep the power flowing wherever we go,

but it could signal the end of the battery as we

know it. In future, that plastic casing on your

smartphone won't just protect the circuits inside;

it will keep them supplied with juice too. The

walls and floors of your home could also do double

duty - as infrastructure that also keeps the

lights burning. Even humble paper could play a

vital role in keeping you switched on.

According to Emile Greenhalgh, one

of the first places you'll notice a difference

will be on your driveway. Though your next car is

likely to look familiar, its sleek bodywork could

well be made from lightweight composites rather

than steel. And if Greenhalgh, a materials

scientist at Imperial College London, has his way,

this bodywork will help store the energy that your

vehicle's electric motor needs for the daily

commute. "We think the car of the future could be

drawing power from its roof, its bonnet or its

door," he says.

His vision emerged in 2003, when he was

approached by researchers from the UK government's

research agency, the Defence Science and

Technology Laboratory. They were after a new

material for uncrewed aerial vehicles that would

be strong enough to bear a load but could also

store electrical energy. Greenhalgh and his

colleagues were intrigued and set out to design

one.

They began with a material that is already

revolutionising the aerospace industry: carbon

fibre. The stuff is renowned for high strength and

low weight. When used to reinforce plastic resins,

it forms a tough composite used in Formula One

racing cars and new passenger jets like Boeing's 787

Dreamliner. Though carbon-fibre composites are

not known for electricity storage, the fibres are

good electrical conductors - useful when you want

them to store charge. "Some commercially available

carbon fibres perform really well as electrodes,"

says Leif Asp of the Swerea Sicomp research

institute in Gothenburg, Sweden. "That was not

what we expected."

Rather than building a battery, Greenhalgh

decided to focus efforts on developing another

energy-storage device: a capacitor, or in this

case a souped-up "supercapacitor". A battery has

two electrodes separated by an electrolyte. The

difference in electric charge between the

electrodes causes charged ions to flow through the

electrolyte when the battery is part of a circuit,

causing current to flow. Batteries therefore store

electricity in chemical form, while in capacitors

all the charge accumulates on the electrodes, and

an insulating layer keeps these charges apart. The

solidity of a capacitor is what makes them easier

to adapt for load bearing.

The key to creating a capacitor that can

store electricity in amounts useful to your

gadgets is to maximise the electrodes' surface

area. So Greenhalgh coated each carbon fibre with

a bristling layer of conducting carbon-nanotubes.

He then weaved this furry spaghetti into two flat

electrodes, added an insulating fibreglass layer

between them, and encased the lot in a polymer

resin.

The nanotubes brought an unexpected

benefit - they not only stored a lot of charge,

but they made the supercapacitor panel extremely

strong. In part, this is down to their surface

area, which helps to create a better bond between

the fibres and the resin. The nanotubes also act

like guy ropes, extending out from the slender

carbon fibres and helping to stop them from

buckling under a load. The result is a tough,

lightweight panel that can store 1 watt-hour per

kilogram, around 1/20th of the capacity of a

conventional supercapacitor (see

chart).

Greenhalgh now heads a European-wide

project called Storage, which, in partnership with

Volvo, aims to construct a hybrid-electric car in

which a large steel panel in the vehicle's floor

will be replaced by a composite

supercapacitor. By shrinking the main battery

and eliminating heavy steel, the panel should

shave some 15 per cent from the vehicle's weight.

However, though Greenhalgh is confident he can

improve on his supercapacitor's existing storage

capacity, he admits that you will probably never

drive an electric vehicle powered solely by such

capacitors as they are unlikely to ever match the

capacity of lithium-ion batteries.

Lightweight laptops

Still, such panels offer significant

advantages, particularly for hybrid cars with

regenerative braking, which slows a car by

converting the kinetic energy of movement into

electrical energy. Supercapacitors are perfectly

suited for collecting these short bursts of energy

and putting it back into the system when they

accelerate. That means the main battery can be

smaller and lighter, and should last longer in

service.

That said, other members of the Storage

consortium are still keen to entirely eliminate

conventional hybrid-vehicle batteries. Asp, in

particular, wants to turn lithium-ion batteries

themselves into structural composites. Again,

carbon fibre is a surprisingly good place to start

as one of the electrodes in a conventional

lithium-ion battery is usually made from graphite,

and carbon fibres are essentially graphite

threads.

Batteries are tricky to adapt to a dual

role, though, because their electrolyte is often a

gel or liquid. So Asp's team is formulating a mix

that incorporates a tough polycarbonate as well as

a liquid electrolyte. Asp claims its capacity will

eventually match that of existing lithium-ion

batteries.

Asp's "composite battery" could eventually

offer lightweight versions of conventional laptops

and cellphones, or new designs that run for longer

without needing a recharge. However, that might

not happen overnight, as carbon-fibre composites

aren't cheap. When they are eventually

commercialised, structural batteries are likely to

appear only in the most expensive products at

first. That might not include cars, though. "What

Volvo has found with electric cars is that steel

is too heavy. They have to go to composite cars

anyway," says Greenhalgh. "Our material gives a

bonus."

Structural batteries need not always be

expensive, though; they can also be based on

seriously low-tech materials - stuff so cheap that

you wouldn't think twice about parking your car

right on top of it. In 2007, two researchers at

the University of Cambridge laid the foundations

for a future in which concrete walls, floors and

even driveways could double up as huge batteries.

Gordon Burstein and Erek Speckert reckoned that,

because concrete contains millions of tiny

water-filled pores, it should behave like an ionic

conductor. When sandwiched between a steel cathode

and an aluminium anode, their prototype battery

did produce a trickle of current - until the

electrodes succumbed to corrosion (ECS

Transactions, DOI:

10.1149/1.2838188).

This unpromising start has inspired fresh

attempts, however, including a concrete

zinc-carbon battery created by a team at the State

University of New York at Buffalo. The anode of

their three-layered concrete composite contains

carbon black and zinc powder while the cathode

contains carbon black and manganese dioxide powder

(see diagram). The idea is that these finely

dispersed materials improve electrical

connectivity between the electrodes and the

electrolyte, and this works, up to a point. Tests

show their battery's storage capacity is still

minuscule - just microwatt-hours per kilogram -

but the researchers say that adding salts or

polymers to tune electronic and ionic conductivity

should improve its performance (Cement and Concrete

Composites, vol 32, p 829).

Considering that the average American

house contains over 12 tonnes of concrete and a

small office block might use a thousand times

more, concrete batteries would seem to offer huge

capacity for electrical storage, particularly in

off-grid buildings, as emergency back-up supplies

for businesses or for smoothing the output from

roof-mounted photovoltaic panels. For now, though,

you are more likely to be plugging in to your

wallpaper than to the wall behind it.

Paper-thin batteries are already highly

desirable for powering circuitry in everything

from electronic newspapers to the ultimate geek

chic: clothing with gadgets like phones and

music-players built in. Shreefal Mehta thinks that

paper itself holds the key.

Mehta runs the Paper Battery Company based

in Troy, New York, and is working towards

electricity-storing sheets that will not only

squeeze into places that conventional batteries

can't reach - thin gaps in cellphone casings, say

- but which could also replace paper and thin

plastic in almost any situation where electricity

storage would be a bonus.

Electric origami

His battery is based on research by a team

at Rensselaer Polytechnic Institute (RPI), also in

Troy, that showed it is possible to store energy

in a sheet of cellulose. The team embedded a

carbon-nanotube array into each side of a

cellulose sheet that had been soaked in an ionic

liquid. The nanotubes formed the electrodes, while

the ionic liquid, dispersed in pores within the

cellulose, acted as an electrolyte. Their material

successfully stored around 10 watt-hours per

kilogram - in other words, a dozen A4 sheets of

the stuff would supply about the same energy as a

typical AAA-battery (Proceedings of the

National Academy of Sciences, vol 104,

p 13574).

Though Mehta declined to reveal much about

the material his company is developing, dubbed the

PowerWrapper, he says their trick has been to

formulate the different components into a

printable ink so that they can create a battery by

printing the layers sequentially. This allows them

to create both supercapacitors and batteries with

high energy-density that can be produced using a

high-speed roll-to-roll manufacturing process.

Mehta plans to commercialise his paper batteries

in the next two years. "We're already in

discussions with customers who are testing our

prototype devices," he says.

Ultimately, the company envisages

integrating their paper battery into the cover or

lining of laptop cases, into car interiors and

homes. A PowerWrapper sheet could do the job of a

conventional membrane laid under the roof or fixed

to exterior or interior walls, while also allowing

you to store renewable energy from photovoltaic

panels or turbines for times when the sun isn't

shining or the wind doesn't blow. "You could wrap

it around any structure," says Pulickel Ajayan,

who helped develop the material at RPI.

So tread lightly on that concrete path.

Close your laptop's lid with care. We may not wave

goodbye to AA-batteries and their ilk for some

while yet, but in the meantime let's show the

everyday materials of modern life the respect they

will soon deserve.

James Mitchell

Crow is a science writer based in

Melbourne, Australia

back to table of

contents |

About Integrity

Research Institute

Future

Energy eNews is

provided as a public service from Integrity Research

Institute, a

Non-Profit dedicated to educating the public

on eco-friendly emerging energy technologies.

FREE copy

of the 30 minute DVD "Progress in Future Energy"

is available by sending an email with "Free DVD" in subject

and mailing address in

body.

Your

generous support is welcome by making a tax

deductible donation on our

secure website | | | |

| Save 10% |

On

all purchases from IRI by becoming a

member and

a free gift when you join and you save 10% on all

conference and workshop fees as well. You

will receive a quarterly mailing with the latest

information on eco-friendly emerging energy

technologies. All 2011 IRI members will receive free

copies of Energy magazines and the latest emerging

energy technologies reports. |

| | | |